A chef’s knife is more than just a tool—it’s an extension of the chef. Whether you’re prepping vegetables for a quick dinner or carving a roast for a holiday feast, the quality of your knife affects your efficiency, precision, and overall cooking experience. This comprehensive guide explores the anatomy of a chef knife, the intricacies of steel types, heat treatment, manufacturing methods, and how brands like Rebex are shaping the mid-tier knife market.

Renowned for its sharpness and edge retention, carbon steel contains 0.6–1.5% carbon. Popular types include:

Pros: Razor-sharp edges, easy to hone, great for professional chefs.

Cons: Prone to rust and requires regular oiling and drying.

With 12–17% chromium, stainless steel offers low-maintenance performance.

Pros: Rust-resistant and durable.

Cons: Often less sharp and requires more frequent honing.

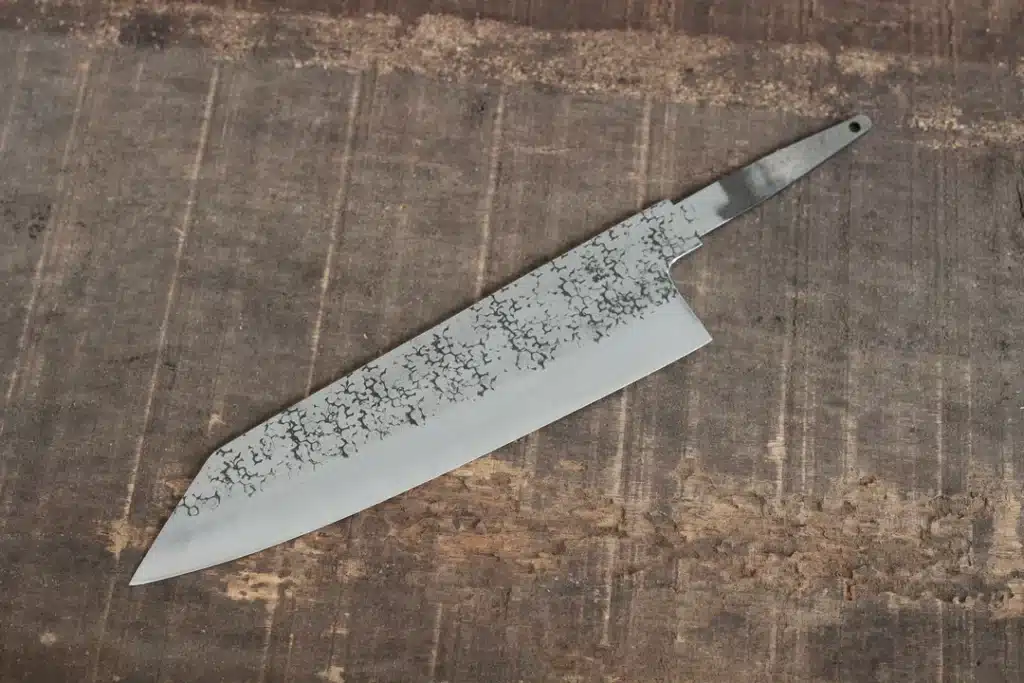

Premium knives use powdered steels like MAGNACUT or ELMAX for extreme performance. Damascus steel, often layered with a high-carbon core, provides aesthetic appeal and excellent cutting ability. Rebex’s Damascus line reaches ~62 HRC, offering excellent edge retention with a decorative finish.

Steel alone doesn’t determine a knife’s quality—heat treatment does. This process fine-tunes hardness and toughness:

Why It Matters: A poorly heat-treated blade—too soft or too brittle—won’t perform well. Top-tier knives have meticulously controlled heat treatment for longevity and edge retention.

Rebex offers two main steel lines:

| Factor | Cheap Knives | Superior Knives |

|---|---|---|

| Steel Quality | Low-grade stainless | High-carbon or alloy steels |

| Heat Treatment | Inconsistent | Precision-controlled |

| Manufacturing | Often stamped | Forged or precision-stamped |

| Edge Retention | Dulls quickly | Long-lasting sharpness |

| Ergonomics | Basic handles | Balanced, comfort-focused designs |

| Craftsmanship | Mass-produced | Hand-finished or tightly controlled |

Why It Matters: A high-quality knife performs better, lasts longer, and is safer to use. Brands like Rebex strike a balance between quality materials and accessible pricing, appealing to both home cooks and culinary enthusiasts.

To Choose Wisely:

To Maintain:

A great chef knife is forged through science, tradition, and precision. From steel selection to heat treatment and final polishing, every detail impacts how it performs in your kitchen. Whether you opt for a Rebex Damascus blade or a Wüsthof classic, understanding what makes a great knife gives you the power to choose wisely—and slice confidently.